The performance of the parts can be confirmed under various test conditions according to the specifications required by the customer.

*We also have an abundant track record of receiving contracts for just testing.

(The entire body of a light automobile can fit inside)

Various small thermostatic chambers are available for testing the physical properties of small parts and materials.

The amount of irradiation energy can be controlled by a weatherometer using a xenon lamp. There are also carbon types.

The performance of the parts can be confirmed under various test conditions according to the specifications required by the customer.

*We also have an abundant track record of receiving contracts for just testing.

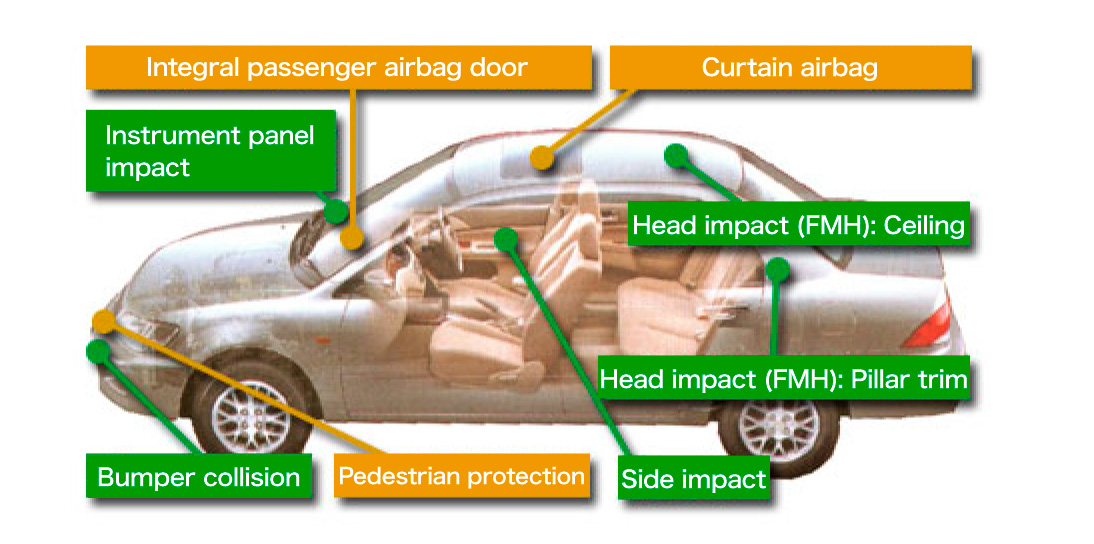

We have also capability for tests equivalent to pendulum collisions, barrier collisions, pole collisions, etc.

Occupant protection is checked with a testing machine, assuming that the occupant on the passenger seat collides with the instrument panel.

A device that simply reproduces the impact of the door trim on the occupants in the event of a side collision, and confirms the amount of energy absorbed and how the door trim will crack.

This test complies with European laws and regulations, JNcap, and EuroNcap. Discharges the leg impactor to check the effects on the knee and shin.

This test complies with the North American regulation FMVSS201. Discharges the Free Motion Headform (FMH) to check the Head Injury Value (HIC).

This is a testing machine for measuring the physical properties of various materials.

*We also have an abundant track record of receiving contracts for just testing.

Equipped with a large surface plate so that it not only implements tensile and compression tests with test pieces, but it can also perform on products such as instrument panels and bumpers.

When guaranteeing the quality of the product, it is very important to evaluate its color tone and texture.

These testing machines measure color tone, gloss, etc. and evaluate whether they conform to inspection standards.

In addition to checking whether there is resonance due to sound or vibration and the generation of chattering sound at the product level, the source of sound can be identified.

*We also have an abundant track record of receiving contracts for just testing.

Vibration tests of large parts such as instrument panels and bumpers can be performed in a 3-axis direction. Furthermore, the vertical direction test can be performed in combination with a thermostatic chamber (-40°C~150°C).

Tests are performed repeatedly at the product level to confirm the durability of the actuating part. It can also perform fatigue tests on materials.

It is also possible to test in an atmosphere of -30°C to 80°C using an assembled thermostatic chamber.