Gas injection

Double shot injection

Low-pressure injection

Preform SPM

Large parts injection with glass fiber

High-cycle injection

Urethane-injected foaming

Core-back foam molding

Concave vacuum forming

Ultra-lightweight thin-wall molding

Airbag door processing technology

・Laser tear processing

・Ultrasonic tear processing

・Cold blade tear processing

Various welding technologies

・Ultrasonic welding

・Impulse

・Vibration welding

Fabric 3D lamination technology

・Kimekomi (Fitting-in)

・Design stitching

Trim piercing technology

・Laser cutting

・Ultrasonic knife

・Press

Bumper coating

Hydrographic printing

Film inserts

Injection

Precision masking coating

Specialized coating

Pad printing

Resin plating

Laser etching

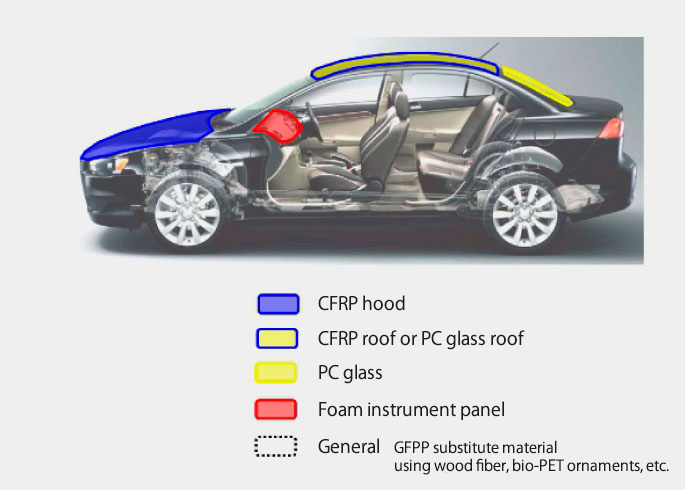

For technological developments in the environmental field, we are working on the development of products using biomass resin (carbon neutrality) and the development of resin outer panels and foamed products (improved fuel efficiency and CO2 reduction by weight reduction).